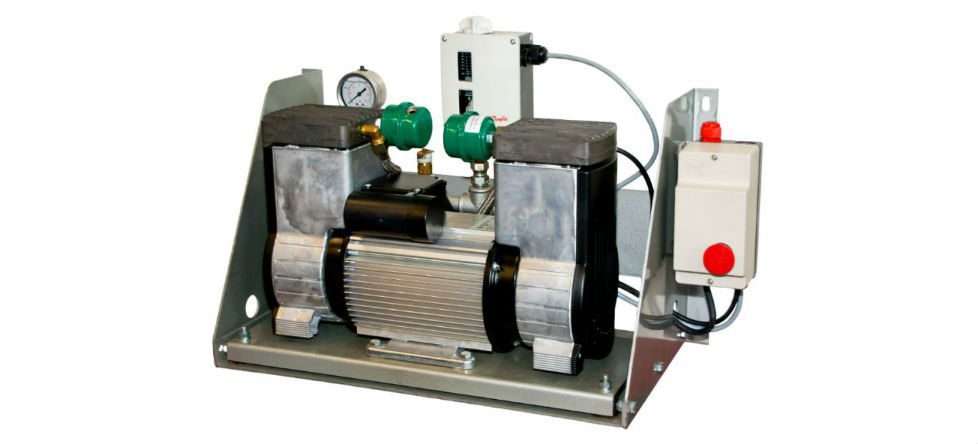

Air compressors have several applications, especially in the industrial sector. Basically, their task is to convert power into pressurised air that is then ready for use.

We use air compressors for different purposes like, for instance, providing pressurised air for driving pneumatic HVAC control system valves in some buildings, we use them for paint spraying or for supplying large-scale industrial processes with moderate-pressure air.

Air compressors can be basically distinguished in two main types: oil-flooded and oil-free air compressors. As they are used in several industrial sectors, sometimes the use of oil as a lubricant is not suitable.

Oil-free air compressors represent the best solution in all sectors where the risk of contaminating products with oil is high. The food and beverage, pharmaceutical or semiconductors industries, for instance, are increasingly opting for oil-free air compressors to be installed in their factories.

Any environment that needs CDA (clean dry air) can benefit from an oil-free air compressor. These have, in fact, more technical development and can deliver better quality air. Not only will the air be cleaner, but also drier and filtered to meet dry nitrogen specifications when needed.

Oil-free air compressors also allow the elimination of the cost and time for changing the oil that traditional oil-flooded compressors require, as well as for the replacement of the downstream filter and the oil separator element. Not to mention the significant energy saving: an oil-free compressor system consumes less energy when unloaded than an oil-flooded one.

Last but not least, oil-free air compressors have less impact on the environment and require less maintenance.

At Sale Engineering Products we have a wide range of oil-free air compressor models, all classified as “silent in operation” and rated for continuous operation. If you need any further information or advice on these systems, please don’t hesitate to contact us. We’ll be happy to discuss your requirements.