As part of our range of booster pump and test equipment, SEP offers this Dry Riser Test Pump unit, available in two sizes (13.5 bar which will cover most UK risers, and 18 bar which is required for Ireland, and some high pressure systems).

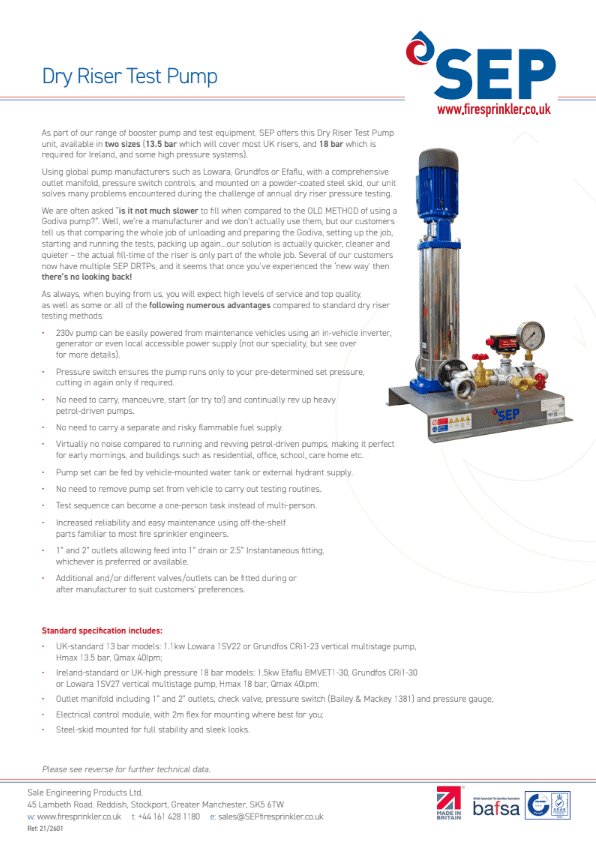

Using global pump manufacturers such as Lowara, Grundfos or Efaflu, with a comprehensive outlet manifold, pressure switch controls, and mounted on a powder-coated steel skid, our unit solves many problems encountered during the challenge of annual dry riser pressure testing.

We are often asked “is it not much slower to fill when compared to the OLD METHOD of using a Godiva pump?”. Well, we’re a manufacturer and we don’t actually use them, but our customers tell us that comparing the whole job of unloading and preparing the Godiva, setting up the job, starting and running the tests, packing up again…our solution is actually quicker, cleaner and quieter – the actual fill-time of the riser is only part of the whole job. Several of our customers now have multiple SEP DRTPs, and it seems that once you’ve experienced the ‘new way’ then there’s no looking back!

As always, when buying from us, you will expect high levels of service and top quality, as well as some or all of the following numerous advantages compared to standard dry riser testing methods:

- 230v pump can be easily powered from maintenance vehicles using an in-vehicle inverter, generator or even local accessible power supply (not our speciality, but see over for more details).

- Pressure switch ensures the pump runs only to your pre-determined set pressure, cutting in again only if required.

- No need to carry, manoeuvre, start (or try to!) and continually rev up heavy petrol-driven pumps.

- No need to carry a separate and risky flammable fuel supply.

- Virtually no noise compared to running and revving petrol-driven pumps, making it perfect for early mornings, and buildings such as residential, office, school, care home etc.

- Pump set can be fed by vehicle-mounted water tank or external hydrant supply.

- No need to remove pump set from vehicle to carry out testing routines.

- Test sequence can become a one-person task instead of multi-person.

- Increased reliability and easy maintenance using off-the-shelf parts familiar to most fire sprinkler engineers.

1” and 2” outlets allowing feed into 1” drain or 2.5” Instantaneous fitting, whichever is preferred or available.

Additional and/or different valves/outlets can be fitted during or after manufacturer to suit customers’ preferences.

Standard Specification Includes

- UK-standard 13 bar models: 1.1kw Lowara 1SV22 or Grundfos CRi1-23 vertical multistage pump, Hmax 13.5 bar, Qmax 40lpm;

- Ireland-standard or UK-high pressure 18 bar models: 1.5kw Efaflu BMVET1-30, Grundfos CRi1-30 or Lowara 1SV27 vertical multistage pump, Hmax 18 bar, Qmax 40lpm;

- Outlet manifold including 1” and 2” outlets, check valve, pressure switch (Bailey & Mackey 1381) and pressure gauge;

- Electrical control module, with 2m flex for mounting where best for you;

- Steel-skid mounted for full stability and sleek looks.

As standard, we’re NOT standard, so we offer the following options:

- Test certificate for pressure gauge – recommended.

- 1” Y-strainer to protect pump from solids contamination – strongly recommended.

- 1” x 1m male-female flexi-hose to connect IBC to pump inlet.

- 5.5mm insulated nut spinner, for adjusting pressure switch.

- Instantaneous adaptors for fire hose.

- Lay-flat hoses complete with instantaneous connections.

- Variable differential (1381V) or higher pressure switch.

- Manifold design and build to suit your individual requirements, including different outlets and connections.

- IBC water tank with adaptors.

Send an enquiry