SEP is pleased to announce that, following a period of development and testing in response to an exciting enquiry and subsequent order from a major customer, we are now able to offer our ‘compressor with receiver’ models with an integrated air maintenance/bypass device.

As most of our customers will be aware, our compressors already incorporate as many of the LPC design guidelines as can practically be accommodated; and the same goes for the FM guidelines in respect of our receiver models. Now we are able to go one step further with this new development which incorporates the following features:

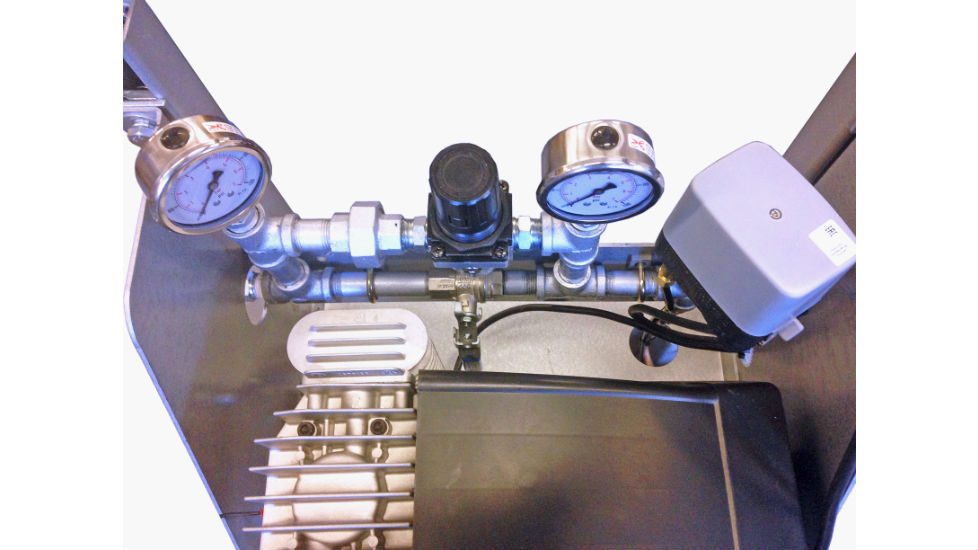

- Safety relief valve, which can be set according to customer requirements

- Standard pressure switch with robust mechanical unloader valve

- Full-bore ½” bypass line for fast-fill, with lockable ball valve

- Maintenance line with fine-control regulator (factory pre-set if required) and restricted orifice

- Two gauges – one for air receiver pressure and one for system pressure

We have worked hard to ensure that the device fits entirely within the existing confines of our wall-mounted framework, thereby taking up no additional space. Of course there is an additional cost for this option, but this is below that of a separate air maintenance device and of course gives greater installation and maintenance convenience.

The development of the integrated air maintenance device is another example of our responsiveness, flexibility and quality drive.